Mining and quarries

The mining and quarrying sector plays a crucial role in the extraction and processing of minerals and rocks. This industry is responsible for supplying raw materials used in various applications, ranging from the construction sector to the production of materials such as cement and ceramics.

In the mining and quarrying sector, transporting large quantities of bulk materials is a complex task that requires efficiency and precision. Additionally, mining and quarrying sites often face challenges such as dust formation, conveyor belt wear, and minimizing material loss. Reducing these issues contributes to a safer work environment, improved productivity, and long-term cost savings.

In addressing these challenges, Promati offers solutions specifically designed for the mining and quarrying sector. Our products provide dust control and wear reduction, enhancing efficiency and ensuring product quality. We understand the unique needs of this industry and strive to provide customized solutions that meet the highest standards of reliability and performance.

Why Blu-Tec in the mining and quarries Industry?

Our Promati products play a crucial role in the mining sector and contribute to optimized bulk handling processes. We offer a wide range of specialized products specifically designed for mining companies.

With Proload Dust Control, mining companies can prevent product loss by creating dust-free transfer points. This is essential as it not only ensures a cleaner and safer working environment but also enables the preservation of valuable materials.

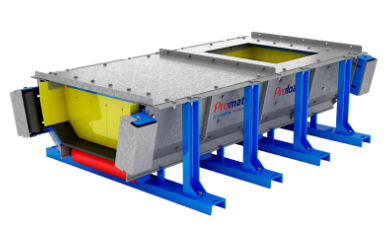

The Flexal Impact Zone provides excellent shock absorption during the transportation of bulk materials in mining applications. This advanced solution reduces conveyor belt wear, lowers maintenance costs, and minimizes downtime.

For mining conveyor belts, Duo Seal is a reliable sealing system with standard clamps. This system prevents leakage and contamination, which is crucial for preserving valuable materials and optimizing the efficiency of mining processes.

Our HDPE rollers are specially designed for the harsh conditions in the mining industry. Made from high-density polyethylene, these durable conveyor belt rollers offer excellent resistance to wear and corrosion, extending the lifespan of the conveyor belts and reducing maintenance requirements.

With these Promati products, mining companies can optimize their bulk handling processes, increase productivity, and reduce operational costs.