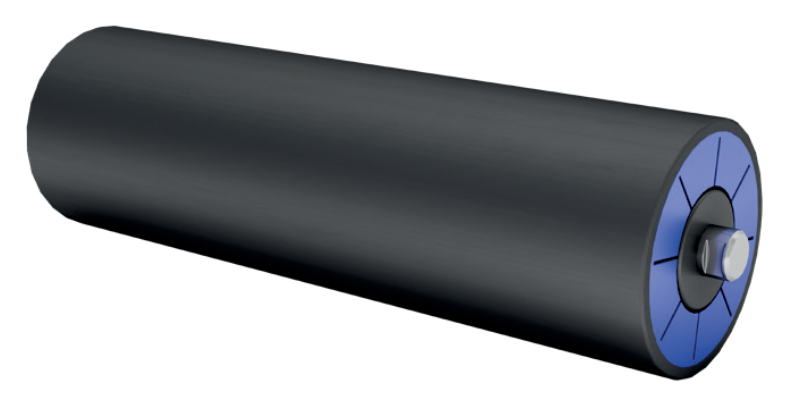

Conveyor rollers made of HDPE

Our HDPE plastic conveyor rollers provide a solution for handling aggressive and adhesive materials, such as various types of fertilizers, clay, compost, and related products. The conveyor roller is designed with a clear goal in mind: to outperform standard steel rollers. Thanks to the use of high-quality HDPE material in the thick wall of the plastic tube and roller base, we can offer exceptional durability and resistance, even in the most demanding conditions.

One of the key features of our conveyor roller is the use of high-quality 2RS bearings. These bearings are not only durable and reliable but also lifetime lubricated, resulting in minimal maintenance requirements. Additionally, our roller is equipped with an advanced sealing system consisting of two chambers, covered with a rubber cap. This provides maximum protection against dust, moisture, and other contaminants, extending the roller’s lifespan and minimizing maintenance costs.

The uniqueness of our HDPE conveyor roller lies in its ability to withstand corrosive chemicals, adhesive substances, and abrasive materials. This translates to a longer lifespan and reduced downtime for your conveyor system.

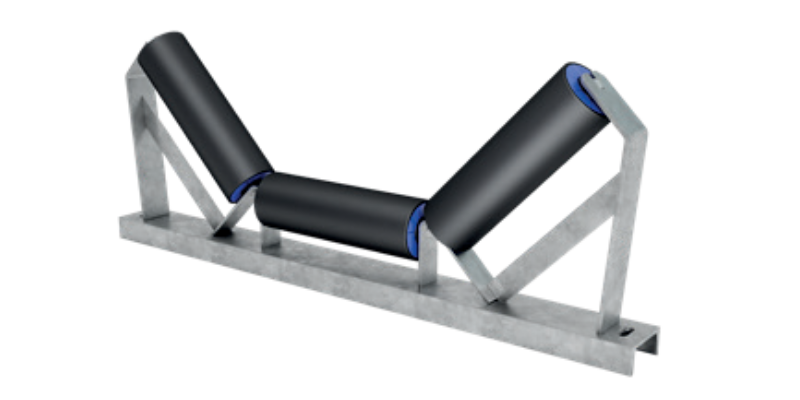

With our HDPE plastic conveyor rollers, you can rely on superior performance and unparalleled reliability. Whether you operate in agriculture, mining, recycling, or any other industry that deals with aggressive materials, our product is specifically designed to increase your productivity and reduce operational costs.

Relevant industries

- Fertilizer industry

- Salt mining and processing

- Sugar industry

- Paper and pulp industry

- Chemical industry – for acids and alkalis

- Coal industry

- cement industry

- Concrete industry

- Limestone mining and processing

Technical information

| Standard dimensions of HDPE rollers | |||||||

|---|---|---|---|---|---|---|---|

| HDPE Tube | Shaft and bearing specifications | ||||||

| Diameter (mm) | Witdh (mm) | ø 20/6204 | ø 25/6205 | ø 25/6305 | ø 30/6206 | ø 30/6306 | ø 35/6207 |

| 89 | 6,4 | V | X | X | X | X | X |

| 102 | 7,0 | V | X | X | X | X | X |

| 108 | 6,9 | V | V | X | X | X | X |

| 114 | 7,0 | V | V | X | X | X | X |

| 127 | 7,8 | V | V | X | X | X | X |

| 133 | 9,0 | X | V | V | V | X | X |

| 152 | 11,2 | X | X | V | V | V | V |

| COMPARISON WITH STEEL ROLLERS (ASTM Test) | |||||

|---|---|---|---|---|---|

| Properties | HDPE ROLLS | STEEL ROLLS | PROPERTIES | HDPE ROLLS | STEEL ROLLS |

| Operation Life Test | E | G | Anti-Static | E | E |

| Dynamic Balancing Test |

E | G | Acid Resistance | E | N |

| Water-Proof Test | E | E | Alkaline Resistance | E | N |

| Abrasion Resistance Test |

G | G | Chemical Resistance | G | G |

| Dust-Proof Test | E | E | Light-Exposure Resistance Test |

G | G |

| Power Saving Operation |

E | N | Ozone Chamber Test | G | G |

| No Miscellaneous Objects Sticking |

E | N | Low Noise Test | E | N |

| Cold Resistance | G | G | Low Friction Rate | E | N |

E = Excellent / G = Good / N = Normal