BLU-TEC Proload

Avoid product loss with dust- and spillage-free loading

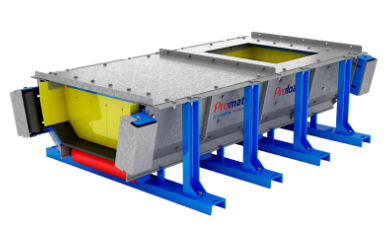

Introducing BLU-TEC® Proload, the ultimate solution for preventing product loss and maintaining a dust- and spillage-free loading process. Designed to exceed industry standards, Proload eliminates the need for traditional side skirt sealing systems, ensuring seamless and efficient loading onto the conveyor belt.

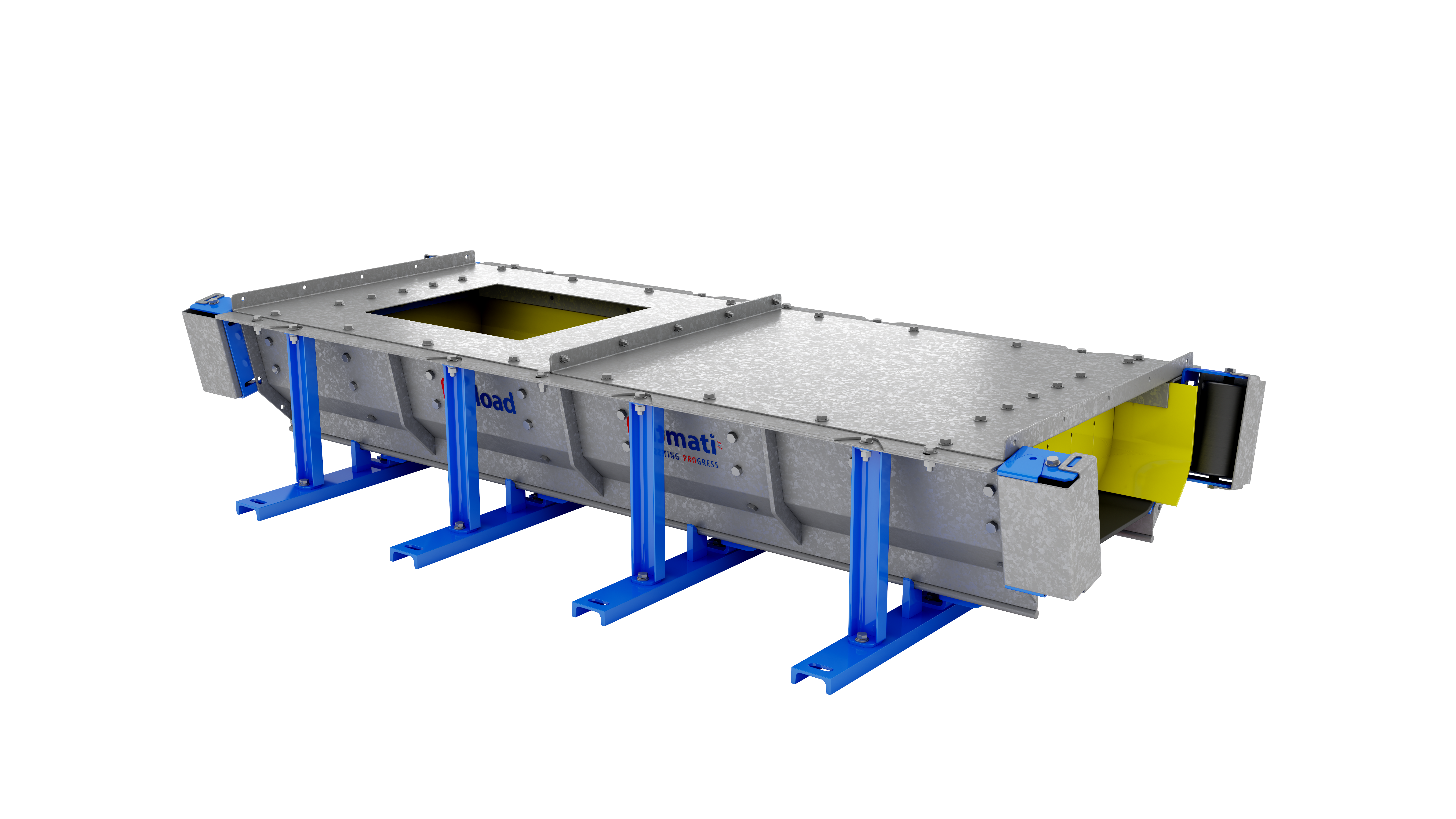

With its innovative design, BLU-TEC® Proload guarantees optimal performance and an easy installation. Each Proload unit is delivered in convenient 2-meter modules, complete with supports, making it suitable for both new conveyor systems and existing conveyors. No more time-consuming and costly procedures – Proload is ready to enhance your loading point right out of the box.

By effectively containing dust and spillage, BLU-TEC® Proload minimizes material loss, improves workplace safety, and reduces environmental impact. The advanced engineering behind Proload creates a tightly sealed loading point, ensuring that your valuable products are securely transferred along the conveyor belt.

Experience the difference with BLU-TEC® Proload. Enhance your loading efficiency, maintain a clean and safe work environment, and eliminate unnecessary product loss. Trust in our cutting-edge technology and elevate your loading point to new levels of excellence.

Benefits of the Proload

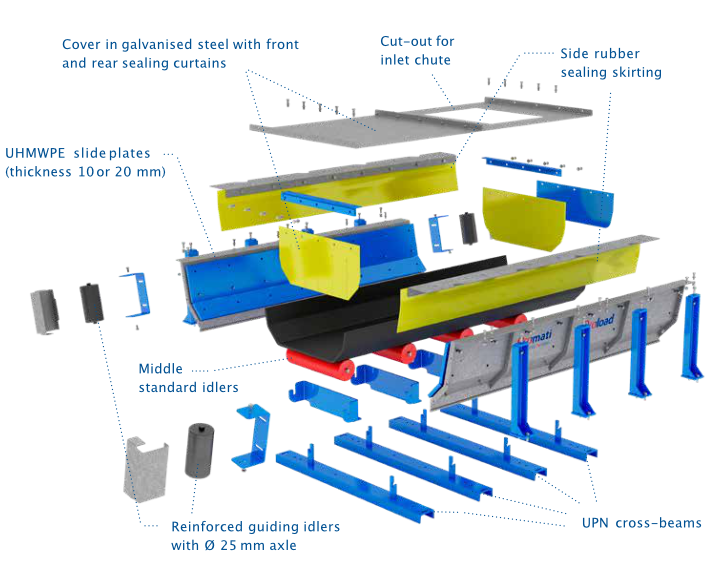

- Modular, customisable design

- Easy to install and maintain, even on existing conveyor systems

- Precise centering of conveyed material

- Heavy, durable construction

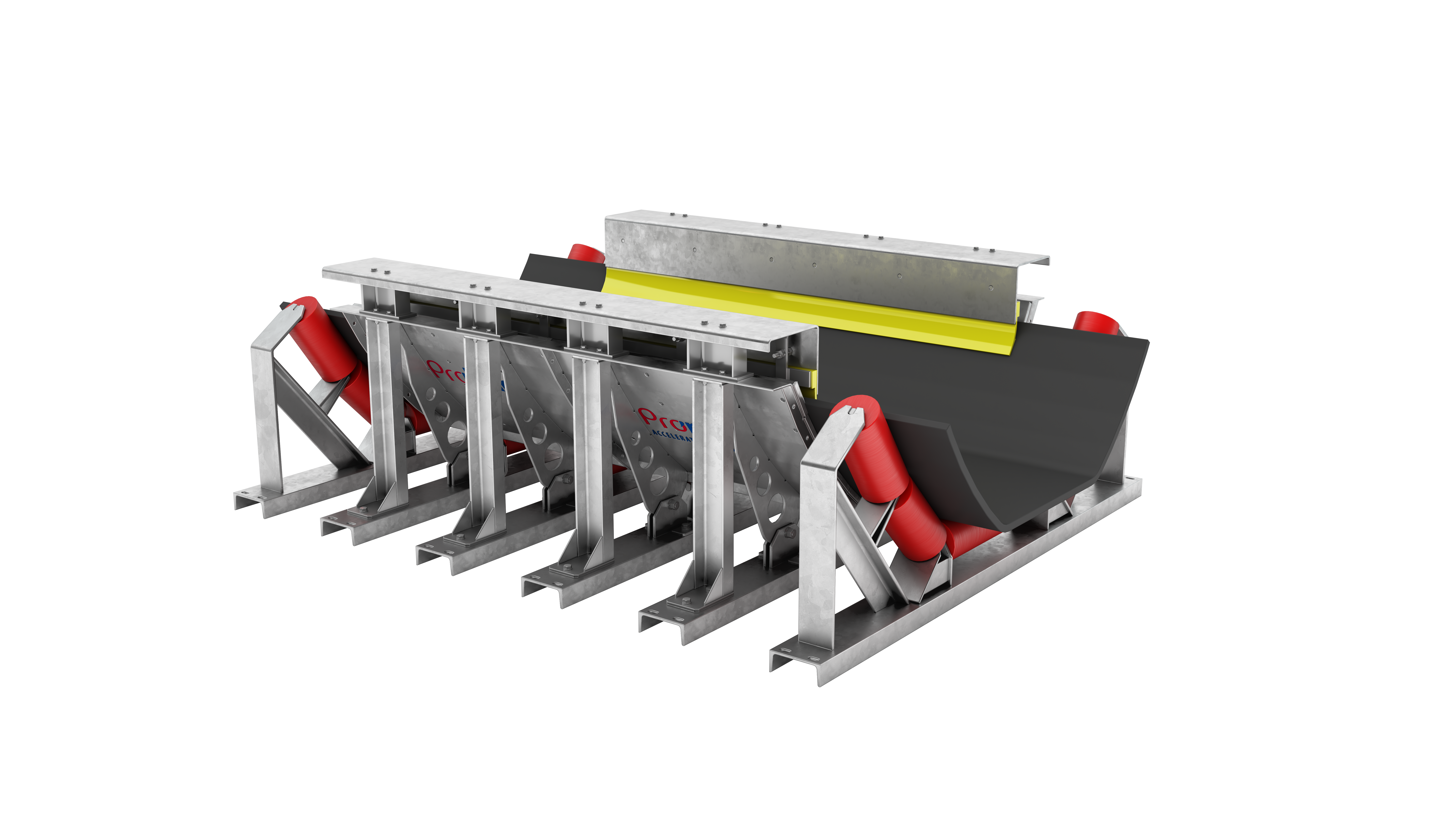

- Reinforced guiding idlers at both ends of the BLU-TEC Proload system

- Also suitable for abrasive materials

3 possible types

- Normal Duty (ND)

- Heavy Duty (HD)

- Extra Heavy Duty (XHD)