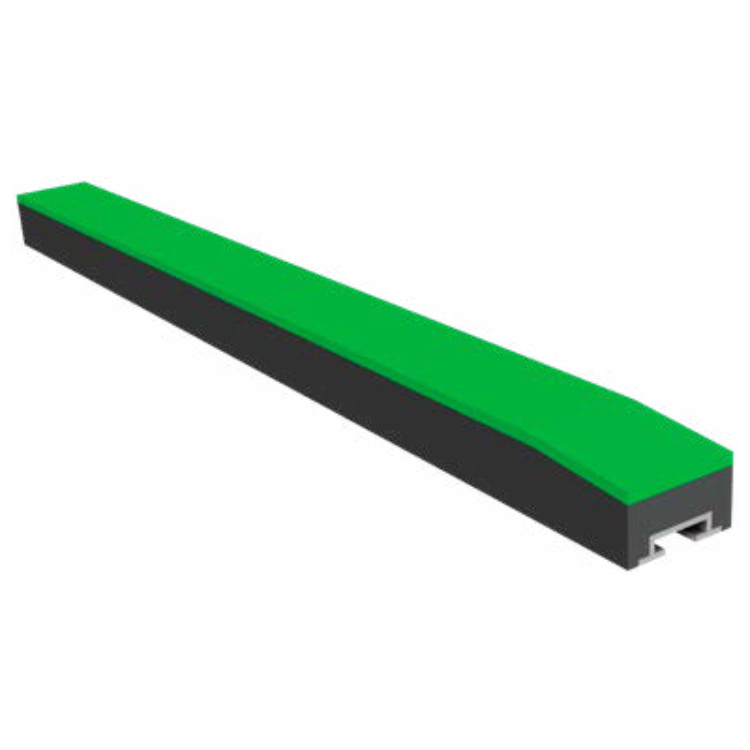

BLU-TEC Impact bars

Blu-Tec Impact Bars provide the ultimate solution for optimizing conveyor systems. A loaded conveyor belt that sags between the rollers can result in product loss and potential damage to the belt. We understand the challenges faced by businesses dealing with heavy impact loads, and that’s why we have developed a pioneering product to address these issues.

Traditional conveyor rollers lack flexibility and support, especially when exposed to heavy impact loads. This not only leads to costly product loss but also increases the risk of conveyor damage and downtime. At Blu-Tec, we strive to offer customized, innovative solutions that deliver exceptional performance, and our Impact Bars are no exception.

Our Blu-Tec Impact Bars, available in standard and heavy-duty versions, create a fully supported impact zone for your conveyor system. By strategically placing our Impact Bars along the conveyor belt, we create a damping effect that absorbs the forces generated during material transfer. This eliminates product loss and minimizes downtime caused by conveyor damage.

What sets Blu-Tec Impact Bars apart is the advanced technology incorporated into their design. The Impact Bars are manufactured using high-quality materials carefully selected to withstand demanding operating conditions. Their composition provides exceptional durability, resilience, and impact resistance, making the Impact Bars a long-lasting and reliable solution for your conveyor system.

With Blu-Tec Impact Bars, you’ll experience smoother material transfer, increased productivity, and a safer working environment. Regardless of the industry you operate in, whether it’s mining, quarries, recycling, or any other field where heavy impact loads occur, our Impact Bars are designed to meet your specific needs. We understand the importance of customized solutions, and our team of experts will work closely with you to achieve the perfect configuration for your conveyor system.

Advantages of the impact bars

- Reduced product loss

- Limited impact on the conveyor belt, resulting in less wear

- Decreased maintenance leads to lower maintenance costs, reduced downtime, and increased revenue

- Extended lifespan of the conveyor belt

- Negligible power loss from the motor

- Easy installation on existing structures

Minimize product loss by utilizing shock-absorbing rubber bars

These bars effectively absorb the impact of materials on the conveyor belt, reducing the likelihood of spillage or loss. By cushioning the impact, the rubber bars help to maintain the integrity of the conveyed products, ensuring that they remain securely on the belt throughout the transportation process. This minimizes waste, improves operational efficiency, and ultimately leads to cost savings.

Recommended number of bars based on belt width

| Bandwith (mm) | Rolllenght (DIN) | # bars | Rolllength (NFE) |

|---|---|---|---|

| 500 | 200 | 2+2+2 | 190 |

| 650 | 250 | 2+2+2 | 240 |

| 800 | 315 | 2+3+2 | 290 |

| 1000 | 380 | 3+3+3 | 360 |

| 1200 | 465 | 3+4+3 | 430 |

| 1400 | 530 | 4+5+4 | 500 |

| 1600 | 600 | 5+5+5 | 570 |

| 1800 | 670 | 5+6+5 | 640 |

| Reference | Width (mm) | Height (mm) | Length (mm) | Weight (kg) |

|---|---|---|---|---|

| H 55x100x1240 | 100 | 55 | 1240 | 8 |

| H 55x100x1500 | 100 | 55 | 1500 | 10 |

| H 75x100x1240 | 100 | 75 | 1240 | 11 |

| H 55x100x1500 | 100 | 75 | 1500 | 14 |

On demand: impact bars with ceramic coating