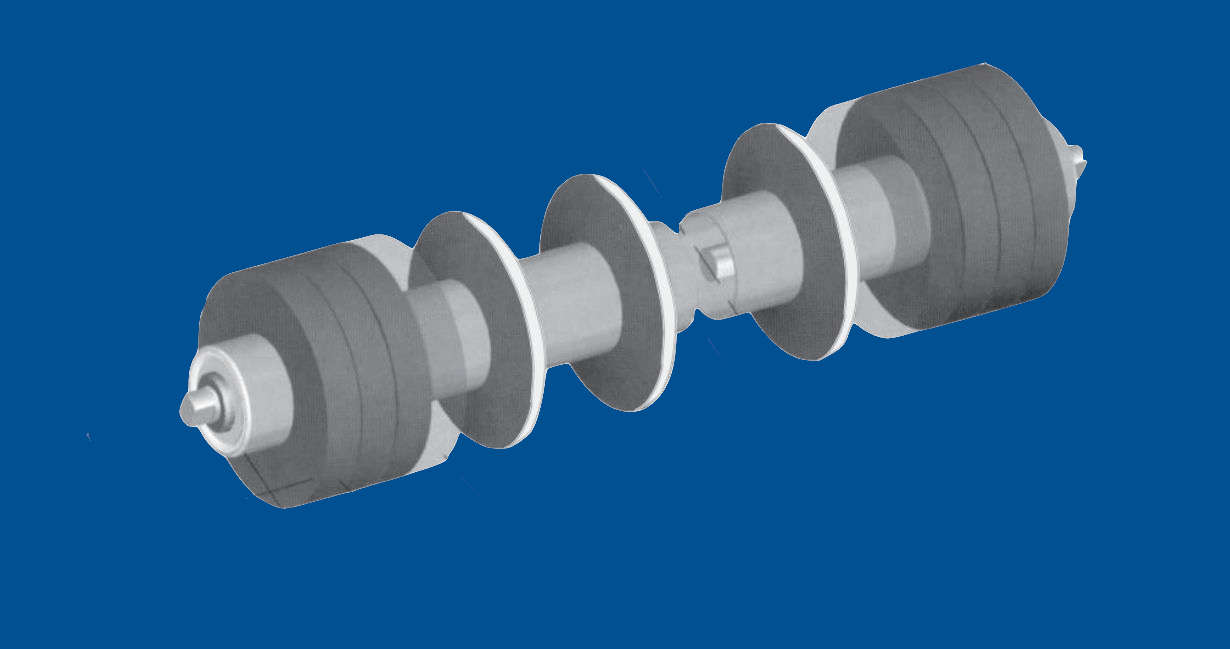

CERAPRO rings for return idlers

The surface in contact with the belt is made of ceramic tiles, compared to the classical ring in rubber. The wear of the rings is hereby drastically reduced. Consequently, the CERAPRO rings should not be replaced rapidly, and can eventually be re-used when the roller is worn out.

Minimize product loss by utilizing shock-absorbing rubber bars

The CERAPRO ring reduces the contact surface between the belt and the roller, which consequently reduces also the losses of product underneath the conveyor. The clogging of the rollers, which causes belt misalignement, is also improved. Considering the longer lifetime compared to standard rings, the changing of the rollers will happen after a longer period (no more wearing of the steel tubes,…..). This reduces strongly the maintenance costs.

Example of distribution of CERAPRO and rubber rings onto the roller in function of the belt width :

| Roller length (mm) | Belt width (mm) | Possible distribution of the rings |

|---|---|---|

| 750 | 650 | Flat sleeve 120 mm – 1 A – 1 C – 1 A – Flat sleeve 120 mm |

| 950 | 800 | Flat sleeve 120 mm – 2 A – 2 C – 2 A – Flat sleeve 120 mm |

| 1150 | 1000 | Flat sleeve 160 mm – 1 A – 3 C – 1 A – Flat sleeve 160 mm |

| 1400 | 1200 | Flat sleeve 160 mm – 2 A – 3 C – 2 A – Flat sleeve 160 mm |

| 1600 | 1400 | Flat sleeve 160 mm – 3 A – 4 C – 3 A – Flat sleeve 160 mm |

| 1800 | 1600 | Flat sleeve 160 mm – 4A – 4 C – 4 A – Flat sleeve 160 mm |

Flat sleeve : Cylindrical rubber rings / Ring A : ovoid rubber rings / Ring C : CERAPRO

Normalized diameters :

∅ tube : 63,5 mm – ∅ outer ring : 108/133 mm

∅ tube : 70 mm – ∅ outer ring : 108/133 mm

∅ tube : 89 mm – ∅ outer ring : 133/159/180 mm

∅ tube : 108 mm – ∅ outer ring : 159/180 mm